Plastic materials are this sort of a fundamental element of our modern planet that we hardly quit to take into account the way they are produced. However, the production procedure for plastic-type is not really as basic as most of us may believe. There are many Rotomolding tactics used to generate plastic material goods, every with its individual group of advantages and disadvantages. Rotomolding is probably the plastic production tactics that have been gaining popularity in recent times. In this particular blog, we shall explore what rotomolding is, the way it operates, along with its benefits, amongst other things.

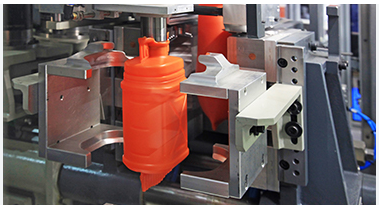

Rotomolding is surely an progressive plastic-type material production technique containing turned on the creation of plastic material items with distinctive forms, dimensions, and designs. Often known as rotational molding, rotomolding requires the use of a hollow mildew filled up with plastic-type material beads that are then heated and rotated around two perpendicular axes. The temperature melts the plastic-type, along with the rotation covers all the types of surface inside of the fungus, creating a easy, hollow plastic material portion.

One of the biggest great things about Rotomolding is it enables companies to create plastic-type things with different wall surface thicknesses, which can not be achieved through injections molding. Also, Rotomolding could be used to generate sizeable components or a number of little components at once, decreasing the expenses related to manufacturing goes and tooling, rendering it ideal for both small and big developing operations.

Another benefit of Rotomolding is the fact contrary to shot and blow molding, Rotomolding makes seamless parts as the whole fungus is spun whilst the plastic-type material remains to be in molten type. Because of this you can find no seams or important joints where plastic material continues to be sewn jointly, generating the ultimate merchandise stronger and regular. Furthermore, rotomolding provides for the roll-out of various finishes and fashoins that can be both visually pleasing and functional.

Rotomolding also allows for more artistic independence from the layout method. Considering that the mold will not be put through extreme strain like injections or blow molding, the options for design are countless. Intricate curves, well-defined ends, and unique geometries can be incorporated into the look. It is then a great process for producing products including gas and drinking water tanks, playground devices, household furniture, and other personalized constructed plastic-type things for a number of businesses.

Simply speaking:

To sum it up, Rotomolding is a amazing new method that has changed the way you make plastic material items. It makes it possible for creative designers and producers to make seamless, hollow plastic-type components with a number of wall structure thicknesses, designs, and fashions. Due to its versatility, durability, and price-efficiency, rotomolding is already the most well-liked process of several sectors, and it’s only improving as developers and engineers continue to innovate and drive the limitations of what is feasible with this technological innovation.